Significant differences between pumps, compressors, blowers and fans are summarized below

Pumps

- A pump is a machine for raising a liquid - a relatively incompressible fluid - to a higher level of pressure or head.

Compressors

- A compressor is a machine for raising a gas - a compressible fluid - to a higher level of pressure.

Blowers

- A blower is a machine for moving volumes of a gas with moderate increase of pressure.

Fans

- A fan moves large amounts of gas with low increase in pressure.

*AIR COMPRESSORS *

The three basic types of air compressors are

- reciprocating

- rotary screw

- rotary centrifugal

These types are further specified by:

- the number of compression stages

- cooling method (air, water, oil)

- drive method (motor, engine, steam, other)

- lubrication (oil, Oil-Free where Oil Free means no lubricating oil contacts the compressed air)

- packaged or custom-built

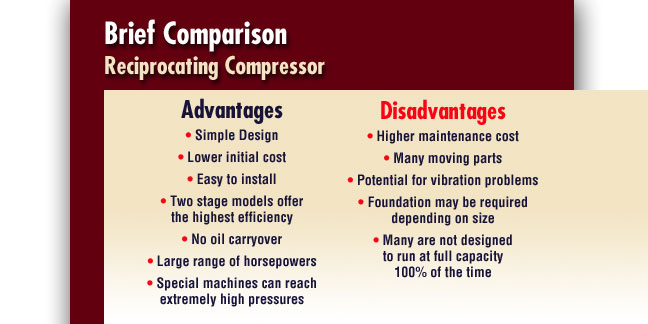

Reciprocating Air Compressors

Reciprocating air compressors are positive displacement machines, meaning that they increase the pressure of the air by reducing its volume. This means they are taking in successive volumes of air which is confined within a closed space and elevating this air to a higher pressure. The reciprocating air compressor accomplishes this by a piston within a cylinder as the compressing and displacing element.

Single-stage and two-stage reciprocating compressors are commercially available.

- Single-stage compressors are generally used for pressures in the range of 70 psig to 100 psig.

- Two-stage compressors are generally used for higher pressures in the range of 100 psig to 250 psig.

Note that

- 1 HP ~ 4 CFM at 100 psi

and that 1 to 50 HP are typically for reciprocating units. Compressors 100 hp and above are typically Rotary Screw or Centrifugal Compressors.

The reciprocating air compressor is single acting when the compressing is accomplished using only one side of the piston. A compressor using both sides of the piston is considered double acting.

Load reduction is achieved by unloading individual cylinders. Typically this is accomplished by throttling the suction pressure to the cylinder or bypassing air either within or outside the compressor. Capacity control is achieved by varying speed in engine-driven units through fuel flow control.

Reciprocating air compressors are available either as air-cooled or water-cooled in lubricated and non-lubricated configurations and provide a wide range of pressure and capacity selections.

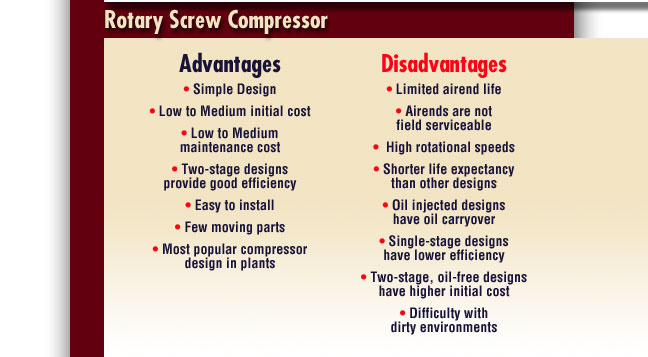

Rotary Screw Compressors

Rotary air compressors are positive displacement compressors. The most common rotary air compressor is the single stage helical or spiral lobe oil flooded screw air compressor. These compressors consist of two rotors within a casing where the rotors compress the air internally. There are no valves. These units are basically oil cooled (with air cooled or water cooled oil coolers) where the oil seals the internal clearances.

Since the cooling takes place right inside the compressor, the working parts never experience extreme operating temperatures. The rotary compressor, therefore, is a continuous duty, air cooled or water cooled compressor package.

Rotary screw air compressors are easy to maintain and operate. Capacity control for these compressors is accomplished by variable speed and variable compressor displacement. For the latter control technique, a slide valve is positioned in the casing. As the compressor capacity is reduced, the slide valve opens, bypassing a portion of the compressed air back to the suction. Advantages of the rotary screw compressor include smooth, pulse-free air output in a compact size with high output volume over a long life.

The oil free rotary screw air compressor utilizes specially designed air ends to compress air without oil in the compression chamber yielding true oil free air. Oil free rotary screw air compressors are available air cooled and water cooled and provide the same flexibility as oil flooded rotaries when oil free air is required.

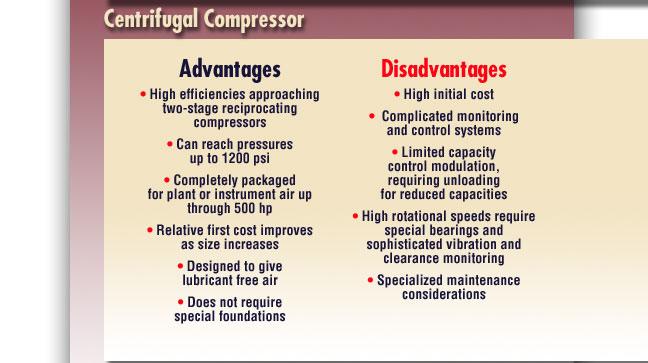

Centrifugal Compressors

The centrifugal air compressor is a dynamic compressor which depends on transfer of energy from a rotating impeller to the air.

Centrifugal compressors produce high-pressure discharge by converting angular momentum imparted by the rotating impeller (dynamic displacement). In order to do this efficiently, centrifugal compressors rotate at higher speeds than the other types of compressors. These types of compressors are also designed for higher capacity because flow through the compressor is continuous.

Adjusting the inlet guide vanes is the most common method to control capacity of a centrifugal compressor. By closing the guide vanes, volumetric flows and capacity are reduced.

The centrifugal air compressor is an oil free compressor by design. The oil lubricated running gear is separated from the air by shaft seals and atmospheric vents.

Air compressors have been used in industry for well over 100 years

because air as a resource is safe, flexible, clean and convenient.

These machines have evolved into highly reliable* pieces of equipment

that are almost indispensable in many of the applications they serve.

Compressors can come in a wide variety of different types and sizes.

because air as a resource is safe, flexible, clean and convenient.

These machines have evolved into highly reliable* pieces of equipment

that are almost indispensable in many of the applications they serve.

Compressors can come in a wide variety of different types and sizes.

Reciprocating or Piston compressors are the most common machines available on the market. They are positive displacement compressors and can be found in ranges from fractional to very high horsepowers. Positive displacement air compressors work by filling an air chamber with air and then reducing the chamber’s volume (Reciprocating, Rotary Screw and Rotary Sliding Vane are all positive displacement compressors). Reciprocating compressors work in a very similar manner as does as internal combustion engine but basically in a reverse process. They have cylinders, pistons, crankshafts, valves and housing blocks.

Rotary Screw Compressors work on the principle of air filling the void between two helical mated screws and their housing. As the two helical screws are turned, the volume is reduced resulting in an increase of air pressure. Most rotary screw compressors inject oil into the bearing and compression area. The reasons are for cooling, lubrication and creating a seal between screws and the housing wall to reduce internal leakage. After the compression cycle, the oil and air must be separated before the air can be used by the air system.

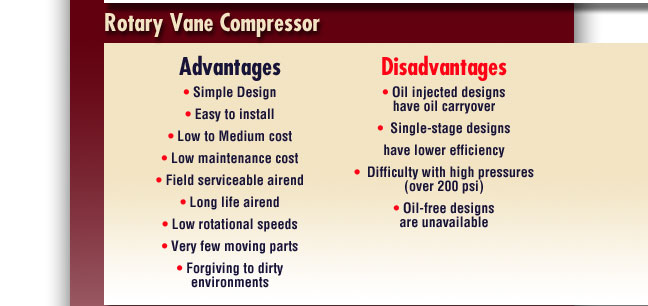

Rotary Sliding Vane Compressors like Reciprocating and Rotary Screw compressors are positive displacement compressors. The compressor pump consists primarily of a rotor, stator, and 8 blades. The slotted rotor is eccentrically arranged within the stator providing a crescent shaped swept area between the intake and exhaust ports. As the rotor turns a single revolution, compression is achieved as the volume goes from a maximum at the intake ports to a minimum at the exhaust port. The vanes are forced outward from within the rotor slots and held against the stator wall by rotational acceleration. Oil is injected into the air intake and along the stator walls to cool the air, lubricate the bearings and vanes, and provide a seal between the vanes and the stator wall. After the compression cycle, the oil and air must be separated before the air can be transferred to the air system.

Centrifugal Compressors are not positive displacement compressors like the Reciprocating, Screw or Vane Compressors. They use very high speed spinning impellers (up to 60,000 rpm) to accelerate the air then diffuser to decelerate the air. This process, called dynamic compression, uses velocity to cause an increase in pressure. In most Centrifugal compressors, there are several of these impeller/diffuser combinations. Typically, these machines have intercoolers between each stage to cool the air as well as remove 100% of the condensate to avoid impeller damage due to erosion.

|

|

|

|